- High quality and low costs.

The house is fully assembled at the factory, which can significantly improve the quality of work and reduce the cost of the product. - Comfort.

The house is completely ready for use – all communications are installed, finishing is done, all necessary equipment and plumbing are installed. - Time-effective

You save time on choosing a project, searching for builders, selecting building materials. You do not spend time monitoring the process of building on the site. The house is assembled at the factory and installed on the site in a few days. - Mobile and easy to install

The house is transported by truck. The house can be installed on one site, and then transported to another. - Ecology.

We save natural resources at all stages of production – wood proceeding does not require a large amount of energy compared to the production of bricks or concrete blocks. We save CO2 emissions by optimizing logistics – we transport the finished module, not the parts, thereby minimizing the number of vehicles. All materials are renewable, that is, if desired, the standard VITHAUS house can be disassembled and its materials used for other projects. The installation technology of the VITHAUS house is designed for a very careful attitude to the site – when installing the house, the soil cover is not disturbed. The house VITHAUS is energy efficient – it consumes a small amount of energy for heating, and due to the large glass area it uses solar energy for heating. - Opportunity to expand.

A small VITHAUS house can become a temporary dwelling for the period of construction of a large house, and then turn into a cozy guest house, or be the main house that can be completed and developed.

- Contract

The contract for the production of the VITHAUS house is signed in the offices of the company. - Payment terms:

Payment is made in the following stages: at the conclusion of the contract,

40% of the cost of the contract for the production and delivery of the house is paid. When the house kit is ready for production,

20% is paid to perform logistics to the installation site. Upon arrival of the house kit at the construction site,

20% is paid. After assembling the house on the foundation and installing the roof, 10% is paid. After the delivery of the finished object, the last 10% is paid. - Is lending possible?

For individuals, we do not have lending partnership programs, but it is possible to buy a house from us on credit. There are no installments.

- VITHAUS is a serial all-season modular house, which takes into account everything necessary for comfortable living outside the city. We made sure that our customers did not spend their time on the interior of the house, on finding and installing the necessary plumbing equipment, electricity and water supply – everything already taken into account and done.

- Our technologies allow you to assemble fully-equipped modules in warm workshops and assemble them on site to a finished house in a short period of time. In addition to fast assembly, the house can also be quickly dismantled and transported to a new site.

- Our houses have panoramic windows which provide natural light in the house and fill the entire space with light and warmth.

- The house can be installed in almost every area, the presence of gas is not a blocking factor, since our house is designed for heating with electric convectors and a heating stove. The slope or uneven surface of the site also does not block the installation, due to the fact that the house is installed on a pile-screw foundation – we have experienced installing houses on a slope of up to 5 meters.

- The VITHAUS house is a space for open-minded people who love to contemplate and get inspired, love to share warmth and comfort, treat not only themselves, but also the environment with care.

- KOSHAUS – typical houses superior comfort with lean to roof. Models: KH-26, KH-53, KH-78, KH-106, KH-132. When making changes to any home of the series at the request of the client, the project is automatically equated to the individual with a corresponding change increasing the cost.

Which foundation required?

- For typical houses – pile-screw foundation with strapping. The minimum height of the foundation above the ground – 30 cm (depending on the slope of the site). Putting a house directly on the ground is impossible – there will be no access to external communications.

Screw piles are screwed to a depth of 1.4 to 5 meters depending on the soil and the slope of the site.The strapping of the foundation is carried out by a channel of P14 and P18 or a 200*200mm wooden bar.

Foundation with a flat area (the difference between the extremes of up to 90 cm above the ground with a recommended foundation height of 50 cm). Piles with a diameter of 108 mm. No foundation reinforcement required.

Foundation with a slope (the difference between the extreme values of more than 90 cm above the ground with a recommended foundation height of 50 cm).

The foundation must be further strengthened with a metal pipe 4x20x60 mm which is welded to the piles crosswise. For individual projects we install the foundations – concrete insulated reinforced concrete slab.

Who makes the foundation?

- Foundation is made by the buyer independently by contacting a specialized company, or by contacting the contractors of VITHAUS.

What is the cost of the foundation?

- The cost of the foundation depends on the model of the house, materials used, the soil and the slope of the site.

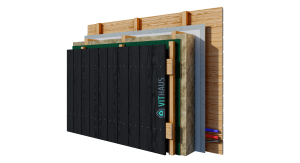

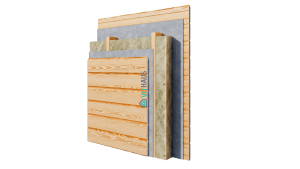

What is the frame made of?

- The frame of the modules is made of a planed technically dried board with dimensions of 45×95, 45×145, 45×195, 45×250 mm. Humidity – 15-18%. Frame reinforcement: LVL timber 51×250/300/400 mm. Reinforced fasteners used to assemble.

- The outer part of the frame is a vertical and horizontal crate, to which the exterior finish is subsequently fastened – a profiled sheet.

- The interior of the decoration consists of timber imitation and decorative boards.

- Timber – coniferous wood (pine or spruce). Larch optionally used.

What is used to treate the wood?

- The frame is processed by the preserving indelible antiseptic. It protects the wood from damage by wood-destroying and wood-staining mold fungi, algae, mosses, and also wood-nesting insects for up to 35 years.

- The external visible part (the frame of the veranda, the external wooden finish and the decking) is treated with German paints SIKKENS or Belgian oil Rubio Monocoat (optional).

- Interior – covered with water-based paints SIKKENS.

What is module?

- VITHAUS house is a module construction. Each part of the house planning is a separate element – a module. All modules are fully staffed at the factory and delivered as a finished product to your site for installation.

- For example, a module with a bathroom – a block with an installed washbasin, toilet, shower or bath (depending on the layout), boiler, warm floor, mosaic and wood trim, sockets and lighting will be delivered to your site. No need to finish and install the necessary plumbing during the installation of the house – everything is ready.

- Windows, doors, panoramic windows are also installed at the factory.

What are the dimensions of the modules?

- Length: 3.1 and 6.6 meters..

- Width: 2, 43 meters

- Height: 2.18 to 3.32 meters.

What are possible modules?

- engineering module,

- flat module,

- residential,

- simple modules.

What features are incorporated in these modules?

- Engineering module – it contains all communications, namely, electrical panel and collector node (“comb”).

- Residential module is a module of a bedroom, living room or cabinet, a set of modules depends on the model of the house.

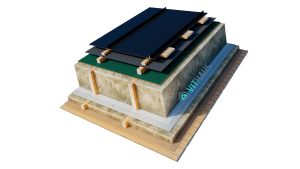

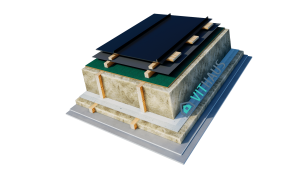

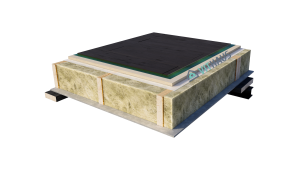

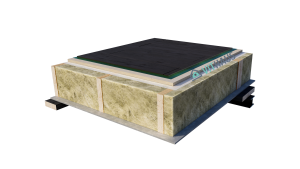

Insulation.

- The unique design of the modules and factory production allows you to warm it as a single integral shell. In the walls, we use high-density stone wool insulation.

- Insulation on both sides of the membrane is closed, which does not allow moisture to come from outside, and at the same time releases condensate from the insulation.

What company insulation is used?

We use insulation by Parok.

What is the thickness of the insulation?

- The floor is 250 mm.

- The walls are 250 mm.

- The roof is 300/400 mm.

Is it possible to order additional warming?

- Yes, it is possible – it is agreed individually.

What electrical power is suitable for our houses?

- For VITHAUS houses electrical power of 10 kW required, the recommended power of 15 kW.

How is the wiring done?

- All wiring is hidden in the frame. The cable is laid in the walls in a flexible self-extinguishing metal-plastic corrugated sleeve. We do not move the wiring out.

- Wire materials – copper.

Which Fuse Box is in the kit?

- The VITHAUS kit, regardless of the model, includes a three-phase Fuse Box 25A of category B.

- Automat 16A for the household sockets.

- Automat 10A is installed for the lighting.

What sockets are installed?

- Ceramic-based two-position sockets. Manufacturer ABB Levit, white.

And what about the lighting?

- The package of each house includes pendant and street lamps.

- IKEA MELODY pendant lights we set as a temporary option, so that after installation you can immediately use the lighting, and later replace them with ones that suit your interior.

Engineering.

Sewage.

- PVC pipe 50 and 110 mm. Connection to external networks – D110.

Plumbing.

- Polypropylene D20, combined with a flexible connector. Connection to external networks – PND32.

- Collector node (“comb”) is located in the engineering module.

Sanitary engineering.

- GROHE blenders. Faience: Spain.

Is there any ventilation?

- Yes, forced from the kitchen and bathroom area (ventilation channel with a diameter of 100 mm), as well as ventilation valves in all rooms (diameter 100 mm).

Glass, Windows, Doors.

What is the size of the doors and windows?

- Window opening – according to the project.

- Entrance door opening – 2160×1000 mm.

- The opening of the interior door – 2100×1000 mm.

- Doorway to the bathroom – 2100×1000 mm.

- The actual size of the door is about 50 mm smaller.

What windows are installed?

- Two-chamber, i-coated inner layer. Behind the stove – tempered glass.

- Thickness of a double-glazed window is 44 mm.

What is the material of the frames?

- Wood. Profile 78 mm.

Heating.

What is the heating system?

- VITHAUS is designed for heating with electric convectors and a fireplace. Water heating is not carried out (the client can install individually).

Is it possible to heat only with a heating stove?

- Fireplace is not the main source of heating.

Are there any restrictions on the regular operation of the heating stove?

- Yes, manufacturers of heating stoves prohibit long-term use of the stove with fully open dampers.

What the fireplace are installed in the VITHAUS houses?

- Model Koza AB/S/N. The buyer can choose the stove-fireplace independently.

Is a fireplace included in the price of the house?

- The fireplace is not included in the basic equipment of the house. (Optional).

What technique is used?

- Depending on the remoteness of the site from factory, delivery is carried out by manipulators or low-sided trawls. Manipulators are usually ordered up to 300 km, trawls are ordered over 300 km.

How many modules can a trailer / trawl handle?

- One manipulator with a body from 7 m with a trailer from 7 m or a trawl can carry 2 modules.

Who delivers?

- VITHAUS contractors.

What is the cost of delivery?

- Delivery cost depends on the model of the house and the distance.

- The cost is calculated on the basis of the freight carrier’s fare, which is 2,20 euro / km. Terms of shipment FCA seller’s warehouse.

- The exact cost of delivery of your house will be calculated while preparing commercial proposal.

Is it possible to pick up modules myself?

- Yes, but the installation will nevertheless be carried out by a certified brigade of VITHAUS or its official partner.

Important! The buyer is responsibile for access roads to the site and successful passage of equipment (truck crane, manipulator).

Who carries out the installation?

- Installation is carried out only by certified VITHAUS staff.

Where does the installation team live during the installation process?

- Buyer.

What are the installation terms?

- All modules are installed on the foundation in 1-3 day, then the modules are connected, the house is switched to external networks, the final interior and exterior finishes.

- Installation usually is finished from 3 to 21 days, depending on the model of the house and favorable weather conditions.

Is it possible to mount a house in the rain?

- If heavy rain – no. Light rain does not interfere with installation.

What is the cost of installation?

- Installation is included in the price of the house.

Will there be additional installation costs?

- Yes, at any distance from the factory additional costs as follows:

- Crane: based on the tariffs of local organizations, hour / shift (shift – 8 hours).

- Plot with a slope: additional rental of scaffolding.

- Seasonal installation: joint tariff.

Is it possible to dismantle and transport the house to another site?

- Yes it is possible. The cost of dismantling, taking into account the transportation of modules and installation on the new site will be about 20% of the value of the house.

What communications do VITHAUS house need?

- Plumbing, sewerage and electricity. Gas is not needed.

Should communications be laid inside the house?

- No. All communications are already being divorced around the house. The house can only be connected to external networks.

Who makes the connection on the site?

- Establishing communications with the site and connecting them to the fund is the buyer’s responsibility.

Who connects VITHAUS home to external networks and when?

- The house is connected to external networks only by VITHAUS specialists, as it is necessary to check the operation of the entire system. If communications are connected to the foundation before installation, the VITHAUS team will connect the house to external communications during installation, if communications are not completed, it is necessary to order an additional arrival of VITHAUS specialst.

What should be done first: the foundation or the connection of communications to the installation site of the house?

- As a rule, communications are located near the edge of the foundation, so it is better to first tighten the piles and scald the foundation, and then lay communications to the points indicated on the foundation diagram. It is easier to link three points of communication output to a pile field than 20 piles to communication outputs.

And if the pipes freeze under the foundation, because the space from the ground to the house is not closed?

- For non-freezing of the water supply between the land plot and the house, we recommend using a heating cable that is mounted directly to the water supply. To install the heating cable in the system, inputs are provided in advance. Sewerage does not require a heating system.

We live in a cold region. We are afraid that the insulation of 150 mm is not enough. Is it possible to make it warmer?

- Our experience in monitoring customers’ houses suggests that if a house is of a small area (up to 60 m2), then there is no sense in warming it in addition. Thermal insulation of walls of 250 mm and a roof of 300 mm gives a very good indicator of thermal conductivity. A small amount will be spent on heating due to small volumes of the room.

How the floors, walls, roof are insulated?

- Floors, walls, ceilings in the VITHAUS house are warmed equally “in a circle”. Our design excludes blowing in corners, points of joints.

- The joints between the modules are sealed with a wood-fiber board of Isoplat 12mm. After that, the modules are “tightly” bolted together through the beams around the perimeter from floor to ceiling.

What insulation is used?

We use PAROC insulation. These mats are of increased elasticity and strength with low values of thermal conductivity:

- In the insulation do not contain phenol-formaldehyde resins. Insulation has no chemical smell;

- Made on the basis of natural components, is nature and human-friendly;

- Fireproof. Recommended for use in all climatic regions.

Shall the insulation not slip?

This is impossible because of the design features and technology used for laying insulation:

- Since the frame of the house is assembled from 45 × 195 lumber, in the basic version we use 2 layers of insulation 100 mm each. Total thickness of insulation is 200 mm. The “extra” 5 mm of insulation, which extend beyond the framework, “bulging out” create additional friction between the layers of insulation and windscreen and spring up the insulation, pressing it back through the crate through the layer of wind protection. In the walls, we use insulation of high density and rigidity of 45-50 kg/m3.

Windows energy efficiency.

- When choosing a glass unit, an important role is played not only by the number of cameras, but also by the thickness and additional layers that increase energy efficiency. We use a two-chamber glass unit consisting of three layers of glass. The total thickness of the glass unit is 44 mm, which significantly exceeds the standard budget options with a thickness of 32-36 mm.

- The Internal and external layer of glass is covered with a special energy-efficient coating that prevents heat loss and protects the room from overheating in the summer.

- Energy efficiency is determined by the heat transfer coefficient Ug = 1,00.

- In the double-glazed windows that we use in our large facades Ug = 1,00. This is achieved due to the metallized coating, which limits the absorption and transmission by the glass of thermal radiation and increases the reflectivity of the glass unit in the wavelength region characteristic of thermal radiation inside the room.

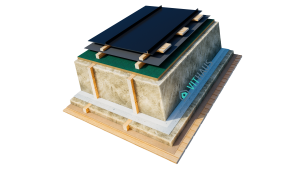

What is included in the basic equipment of a standard house?

Roof: 307/357 mm = 5,40/6,39 m² K/W, U = 0,1852/0,1565

Walls: 251/301 mm = 4,46/5,44 m² K/W, U = 0,2242/0,1838

Floor: 285 mm = 4,10 m² K/W, U = 0,2370

Windows: wooden profile 78 mm, U = 1,00

Roofing: any type.

Supporting frame: Wooden antiseptic crate: 23×170 mm.

Wooden antiseptic counter-lattice: 50×100 mm.

Wind and moisture protection: diffusion membrane p=135 g/m2.

Fiberboard wind protection plate: p=180 kg/m3, 25 mm.

Reinforced antiseptic wooden frame: 50×200 mm.

Insulation: stone wool p=45 kg/m3, 200 mm.

Internal insulation of the frame: vapor barrier film p=90 g/m2, 1 mm.

OSB-3 moisture-resistant, structural rigidity: p=650 kg/m3, 18 mm.

Wooden antiseptic crate: 100×50 mm / 50×100 mm.

Insulation: stone wool p=45 kg/m3, 50 mm / 100 mm.

Fire-resistant gypsum board: p=1200 kg/m3, 12 mm.

Interior ceiling finish: any.

Facade: any type.

Supporting frame: Wooden antiseptic crate: 23×170 mm.

Wooden antiseptic counter-grid: 50×100 mm.

Fibreboard: p=180 kg/m3, 25 mm.

Reinforced antiseptic wood frame: 50×150 mm.

Insulation: 45 kg/m3 stone wool, 150 mm.

Internal insulation of the frame: vapor barrier film, p=90 g/m2.

OSB-3 moisture-resistant, structural rigidity: p=650 kg/m3, 12 mm.

Wooden antiseptic crate: 100×50 mm / 50×100 mm.

Insulation: stone wool p=45 kg/m3, 50 mm / 100 mm.

Fire-resistant gypsum board: p=1200 kg/m3, 12 mm.

Interior wall decoration: any.

Finishing of the floor: any.

Load-bearing frame:

The base of the floor panel: moisture-resistant plywood p=750 kg/m3, 21 mm.

Frame insulation: vapor barrier film p=90 g/m2.

Reinforced antiseptic wood frame: 51×300 mm.

Insulation: stone wool p=45 kg/m3, 300 mm.

Protection from wind and moisture: diffusion membrane p=135 g/m2.

Cement-chipboard, p=1250 kg/m3, 12 mm.

The lining bar is antiseptic, painted black, 51×150 mm.

Protection from mice along the contour of the ventilated facade, from below.

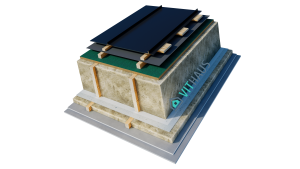

Roof: 407/457 mm = 7.30/8.30 m2 K/W, U = 0.1370/0.1255

Walls: 301/351 mm = 5.40/6.39 m2 K/W, U = 0.1852/0.1565

Floor: 386 mm = 5.98 m2 K/W, U = 0.1672

Windows: profile 78 mm, U = 1.00

Roofing: Any type.

Structural Frame: Antiseptic-treated timber battens: 23×170 mm.

Antiseptic-treated timber counter-battens: 50×100 mm.

Wind and Moisture Barrier: Breathable membrane, density (p)=135 g/m².

Wood fiber wind barrier board: density (p)=180 kg/m³, 25 mm.

Reinforced antiseptic-treated LVL timber frame: 51×300 mm.

Insulation: Rock wool, density (p)=45 kg/m³, 300 mm.

Internal Frame Vapor Barrier: Vapor barrier film, density (p)=90 g/m², 1 mm.

OSB-3 moisture-resistant, for structural rigidity: density (p)=650 kg/m³, 18 mm.

Wooden antiseptic crate: 100×50 mm / 50×100 mm.

Insulation: stone wool p=45 kg/m3, 50 mm / 100 mm.

Fire-resistant gypsum particleboard: density (p)=1200 kg/m³, 12 mm.

Interior Ceiling Finish: Any type.

Facade: any type.

Supporting frame: Wooden antiseptic crate: 23×170 mm.

Wooden antiseptic counter-grid: 50×100 mm.

Fiberboard: p=180 kg/m3, 25 mm.

Reinforced antiseptic wood frame: 50×200 mm.

Insulation: stone wool 45 kg/m3, 200 mm.

Internal insulation of the frame: vapor barrier film, p=90 g/m2.

OSB-3 moisture-resistant, structural rigidity: p=650 kg/m3, 12 mm.

Wooden antiseptic crate: 100×50 mm / 50×100 mm.

Insulation: stone wool p=45 kg/m3, 50 mm / 100 mm.

Fire-resistant gypsum board: p=1200 kg/m3, 12 mm.

Interior wall decoration: any.

Finishing of the floor: any.

Load-bearing frame:

The base of the floor panel: moisture-resistant plywood p=750 kg/m3, 21 mm.

Frame insulation: vapor barrier film p=90 g/m2.

Reinforced antiseptic wood frame: 51×300 mm.

Insulation: stone wool p=45 kg/m3, 300 mm.

Protection from wind and moisture: diffusion membrane p=135 g/m2.

Cement-chipboard, p=1250 kg/m3, 12 mm.

The lining bar is antiseptic, painted black, 51×150 mm.

Protection from mice along the contour of the ventilated facade, from below.

Option-1: PVC, 78 mm profile, 2 sealing contours.

Option 2: Wooden, 78 mm frame, 2 sealing contours.

- Double-glazed windows filled with argon – 44 mm.

- The formula of double-glazed windows: 4ix16Arx4x16Arx4i. U = 1,00.

- Factory lamination or painting, graphite grey RAL 7024.

- Hidden fittings Siegenia Titin AF.

- The doors have reinforced hinges and a mortise lock.

- Stained glass: Reinforced double-glazed windows, filled with argon, tempered glass- 44 mm.

- The formula of double-glazed windows in stained glass: 6i×14Ar×4×14Ar×6i. U = 1,00.

- Sink tap: Grohe BauEdge, chrom.

- Bathroom sink: A furniture washbasin Kolo, complete with a hanging pedestal.

- The toilet is suspended:

Toilet bowl installation Geberit Duofix Plattenbau.

The key Geberit Delta-21 with a double flush.

The toilet is suspended Kolo Novo Pro (Rimfree), microlift seat, color white. - Shower tap: Thermostatic Grohe Grohtherm 800, chrome, complete with shower set Grohe New Tempesta Cosmopolitan 100.

- Shower/Bath:

Option-1 – glazed shower, 900×900 mm;

Option 2 – acrylic bathtub Kolo Comfort XWP3070000, 750×1700 mm. - Water heater: accumulative for 100 liters – The customer buys independently due to the regional warranty.

- Communications for the washing machine: cold water, sewer, outlet.

Kitchen equipment:

- ready–made communications – cold and hot water outlets; sewerage for the sink and dishwasher;

- electrical cable for connecting the hob and oven;

- sockets for the refrigerator and other household appliances.

- installation of the foundation at the facility;

- delivery from the seller’s warehouse to the facility;

- logistics to the installation site and accommodation for installers;

- installation on site;

- rent a 25-ton crane for installation work.

Optionally, additional manufacturing is possible: porches, canopies over the porch, stairs, terraces, verandas, veranda fencing, shutters.